Review of Thermal Runaway Monitoring Circuit Diagram Webinar Overview Thermal runaway in electric vehicle (EV) batteries poses a significant risk. But what triggers it, and how can it be detected and prevented? This webinar will explore the underlying science of thermal runaway, examining the root causes of battery fires and the methods used to predict and detect thermal runaway events. This post presents an example of the Thermal Runaway Modeling and Calibration of an LFP Battery Cell using the ARC device, the HWS test protocol and Simcenter Amesim. An abuse test is the most direct way to challenge the thermal stability limits of a Li-ion cell and characterize the thermal runaway phenomena.

Here, we report a flexible sensor array with fast and reversible temperature switching that can be incorporated inside batteries to prevent thermal runaway. This flexible sensor array consists of PTCR ceramic sensors combined with printed PI sheets for electrodes and circuits.

Techniques to Prevent Thermal Runaway in EV Circuit Diagram

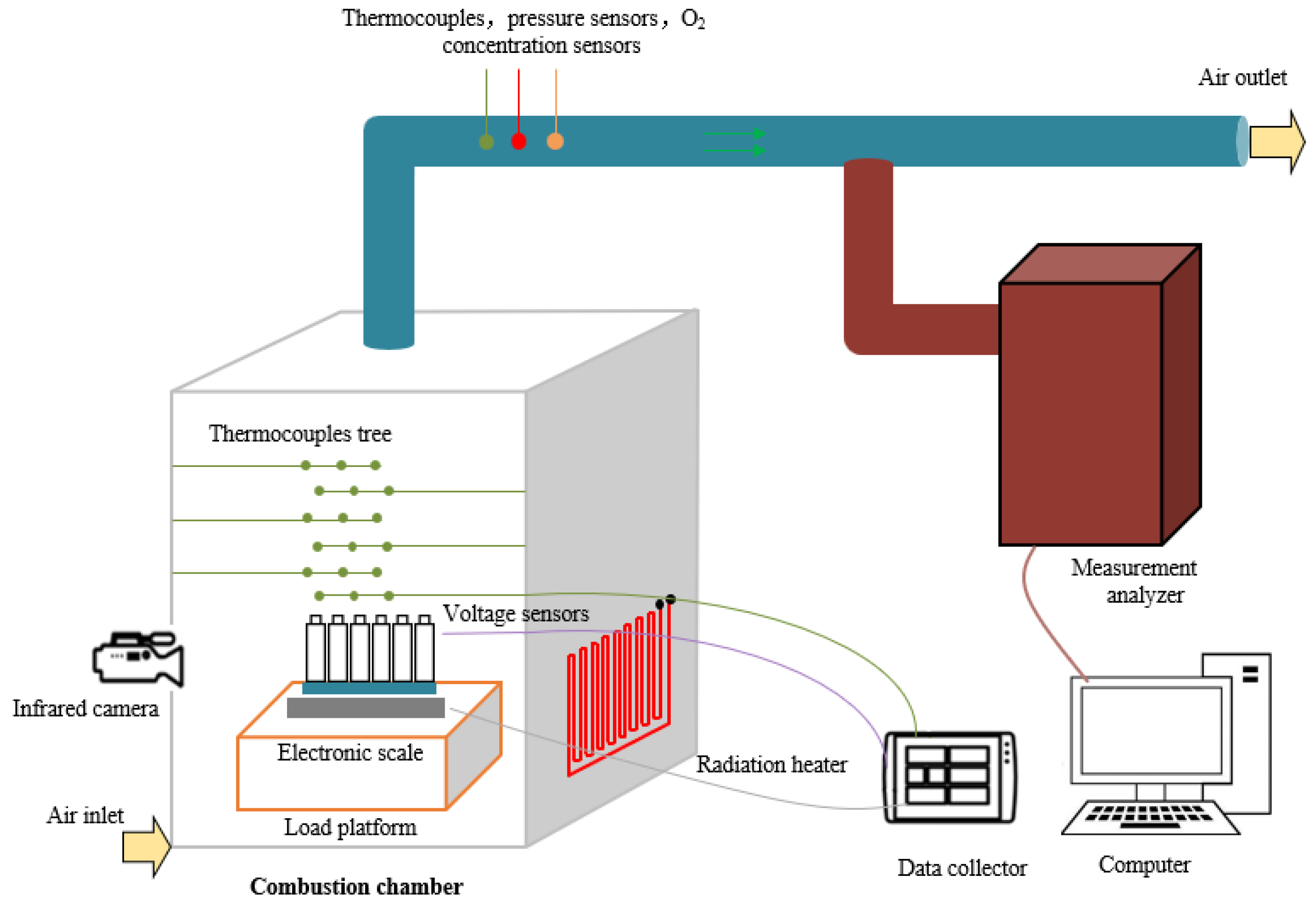

Therefore, monitoring and detecting the incipient-stage thermal runaway by measuring or estimating these characteristic signals, such as the voltage, the temperature, and the gas component, is one of the most effective methods to promote the safety of lithium-ion batteries in different application scenarios.

Authors in ref. 84 modeled early-stage thermal runaway, which was triggered by an internal short circuit, by considering the thermal dynamics of the core, middle, and surface of the battery. This study compares various monitoring, warning, and protection techniques, summarizes the current safety warning techniques for thermal runaway of lithium-ion batteries, and combines the knowledge related to thermal runaway. It also analyzes and forecasts the future trends of battery thermal runaway monitoring, warning, and protection. Creating a model of the thermal runaway process is complex as it covers a large number of subject areas.

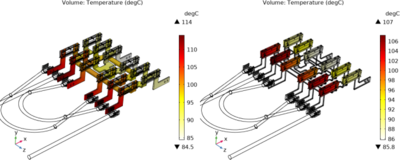

Modelling Thermal Runaway Circuit Diagram

The thermal runaway propagation (TRP) model of energy storage batteries can provide solutions for the safety protection of energy storage systems. Traditional TRP models are solved using the finite element method, which can significantly consume computational resources and time due to the large number of elements and nodes involved. To ensure solution accuracy and improve computational